Industrial Fermenter: Complete Guide to Types, Uses, and Design

An industrial fermenter is a core piece of equipment used in large-scale biotechnological and biochemical production. It provides a controlled environment where microorganisms such as bacteria, yeast, or fungi grow and convert raw materials into valuable products. These products range from everyday food items like yogurt and beer to high-value pharmaceuticals, enzymes, and biofuels. Because of this wide range of applications, the industrial fermenter is often described as the heart of modern fermentation-based industries.

The importance of industrial fermenters has grown rapidly with advances in biotechnology. As global demand increases for sustainable products, renewable energy, and efficient drug manufacturing, fermentation processes offer an environmentally friendly alternative to traditional chemical synthesis. Industrial fermenters allow precise control over growth conditions, ensuring high productivity, consistency, and quality at a commercial scale.

Historically, fermentation began as a simple, natural process used for food preservation. Over time, scientific understanding transformed it into a sophisticated industrial operation. Today’s industrial fermenters are highly engineered systems equipped with sensors, automation, and advanced materials. They play a crucial role in industries such as pharmaceuticals, food and beverage, agriculture, and environmental biotechnology, making them indispensable to modern manufacturing.

Basic Working Principle of an Industrial Fermenter

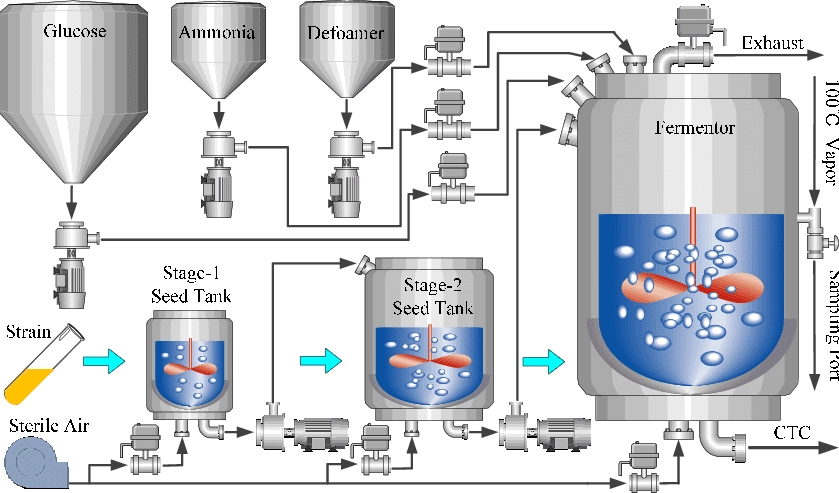

The basic working principle of an industrial fermenter revolves around creating optimal conditions for microorganisms to grow and perform metabolic activities. Inside the fermenter, microorganisms are supplied with nutrients, water, and energy sources, allowing them to produce desired products such as alcohols, organic acids, antibiotics, or proteins. The entire process takes place under carefully controlled conditions to maximize yield and efficiency.

Fermentation can be either aerobic or anaerobic, depending on whether oxygen is required. In aerobic fermentation, oxygen is continuously supplied to support microbial growth, while anaerobic fermentation occurs in the absence of oxygen. Industrial fermenters are designed to support both types, with systems for aeration, agitation, and gas exchange tailored to the specific process requirements.

Key operating conditions such as temperature, pH, dissolved oxygen, and nutrient concentration are continuously monitored and adjusted. Even small deviations can significantly affect productivity. By maintaining stable and optimal conditions, industrial fermenters ensure that microorganisms perform efficiently and consistently, making large-scale production economically viable and scientifically reliable.

Types of Industrial Fermenters

There are several types of industrial fermenters, each designed to suit specific processes and products. Batch fermenters are among the most common types. In batch fermentation, all nutrients are added at the beginning, and the process runs until completion. This method is widely used in pharmaceutical and food industries because it offers simplicity and better control over contamination.

Continuous fermenters operate differently, with fresh nutrients continuously added while products are simultaneously removed. This allows for constant production and higher overall productivity. However, continuous fermentation requires more advanced control systems and carries a higher risk of contamination, making it suitable mainly for well-established processes.

Fed-batch fermenters combine elements of both batch and continuous systems. Nutrients are added gradually during the process, allowing better control over microbial growth and product formation. In addition to these operational modes, industrial fermenters are classified by design, such as stirred-tank fermenters, airlift fermenters, and bubble column fermenters. Each type offers unique advantages in terms of mixing, oxygen transfer, and energy efficiency.

Design and Construction of Industrial Fermenters

The design and construction of an industrial fermenter are critical to its performance and durability. Most fermenters are made from high-grade stainless steel, which is resistant to corrosion, easy to clean, and capable of withstanding high pressure and temperature. The vessel shape is carefully designed to promote efficient mixing and heat transfer while minimizing dead zones.

Agitation systems, including impellers and stirrers, ensure uniform distribution of nutrients, microorganisms, and gases throughout the fermenter. Proper mixing prevents sedimentation and improves mass transfer, which is essential for microbial activity. Aeration systems, such as spargers, supply oxygen in aerobic processes and play a key role in maintaining dissolved oxygen levels.

Temperature control is achieved through cooling jackets or internal coils, allowing excess heat generated during fermentation to be removed. All these design elements work together to create a stable and efficient fermentation environment. A well-designed industrial fermenter not only improves productivity but also reduces operational costs and maintenance requirements.

Key Components of an Industrial Fermenter

An industrial fermenter consists of several key components that work together to ensure efficient operation. The fermentation vessel itself is the main chamber where microbial growth and product formation occur. It is designed to be airtight, sterile, and strong enough to handle internal pressure.

Agitators and impellers are essential components responsible for mixing the contents of the fermenter. They help distribute nutrients evenly and improve oxygen transfer. Spargers introduce air or gases into the system, which is especially important for aerobic fermentation processes.

Modern industrial fermenters are equipped with sensors and probes that monitor parameters such as pH, temperature, and dissolved oxygen. These sensors are connected to automated control systems that adjust conditions in real time. This level of control ensures consistent product quality and minimizes human error, making industrial fermentation more reliable and scalable.

Sterilization and Contamination Control

Sterilization is a crucial aspect of industrial fermentation, as contamination can ruin entire batches and lead to significant financial losses. Industrial fermenters must be thoroughly sterilized before use to eliminate unwanted microorganisms that could compete with or harm the production strain.

Common sterilization methods include steam sterilization, chemical sterilization, and filtration of air and nutrients. Many modern fermenters use Clean-in-Place (CIP) and Sterilize-in-Place (SIP) systems, which allow cleaning and sterilization without dismantling the equipment. This saves time and ensures consistent hygiene standards.

Contamination control also involves maintaining sterile conditions throughout the fermentation process. Proper sealing, filtered air supply, and strict operational protocols help prevent microbial intrusion. Effective sterilization and contamination control are essential for maintaining product quality, safety, and regulatory compliance.

Applications of Industrial Fermenters

Industrial fermenters are used across a wide range of industries. In the food and beverage sector, they are essential for producing products such as beer, wine, yogurt, cheese, and vinegar. These applications rely on fermentation to enhance flavor, texture, and shelf life.

In the pharmaceutical industry, industrial fermenters are used to produce antibiotics, vaccines, hormones, and therapeutic proteins. These high-value products require precise control and sterile conditions, which modern fermenters provide. Industrial fermenters are also widely used in enzyme production for detergents, textiles, and food processing.

Additionally, industrial fermenters play a key role in biofuel production, including ethanol and biogas. They are increasingly important in environmental biotechnology, where they are used for waste treatment and pollution control. This wide range of applications highlights the versatility and importance of industrial fermenters in modern society.

Scale-Up and Optimization Challenges

Scaling up fermentation from laboratory to industrial scale presents several challenges. Conditions that work well in small reactors may not translate directly to large fermenters. Issues such as oxygen transfer, heat removal, and mixing become more complex as volume increases.

Optimization is essential to overcome these challenges. Engineers use advanced modeling, pilot studies, and process control strategies to improve performance. Adjustments to impeller design, aeration rates, and feeding strategies help maintain efficiency at large scales.

Despite these challenges, successful scale-up allows industries to meet global demand efficiently. Continuous innovation in fermenter design and process optimization ensures that industrial fermentation remains a competitive and sustainable production method.

Conclusion

Industrial fermenters are the foundation of large-scale fermentation processes that support food production, healthcare, energy, and environmental sustainability. By providing controlled conditions for microbial growth, they enable efficient and consistent production of valuable products. As technology advances, industrial fermenters continue to evolve, offering greater automation, efficiency, and sustainability. Their role in shaping the future of biotechnology and industrial manufacturing cannot be overstated.

Frequently Asked Questions (FAQs)

What is an industrial fermenter?

An industrial fermenter is a large-scale bioreactor used to grow microorganisms for producing useful products.

What industries use industrial fermenters?

They are used in food, pharmaceuticals, biotechnology, biofuels, and environmental industries.

Why is sterilization important in fermentation?

Sterilization prevents contamination and ensures product quality and safety.

What are the main types of industrial fermenters?

Batch, continuous, and fed-batch fermenters are the most common types.

How does an industrial fermenter differ from a laboratory fermenter?

Industrial fermenters are larger, more automated, and designed for commercial-scale production.

You May Also Read: GCSE Maths Differentiation